Project Description

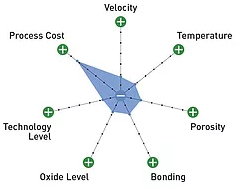

FLAM SPRAY COATING PROCESS

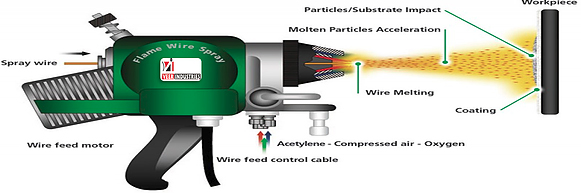

FLAM WIRE SPRAY COATING PROCESS

This is a useful process for applying relatively inexpensive coatings that typically contain high levels of oxides and porosity together with the option of achieving a rough surface finish. The process relies on the chemical reaction between oxygen and a fuel of combustion to produce a heat source. This heat source creates a gas stream with a temperature in excess of 3,000°C with correctly balanced conditions between oxygen and acetylene.

The feed stock material to be sprayed is fed into the flame in the form of a wire and compressed air is then used to atomize the molten metal and accelerate the particles onto the substrate.

Among others, the process is typically used for applying bond coat materials or materials for corrosion resistance applications.

Typical coatings

- Iron based alloys

- Nickel based alloys

- Molybdenum

- Copper & Copper alloys

- Aluminium, Zinc, Al/Zn alloys

Main applications

- Wear resistance

- Friction properties

- Corrosion protection

- Dimensional restoration

- Electromagnetic shielding

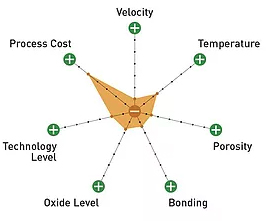

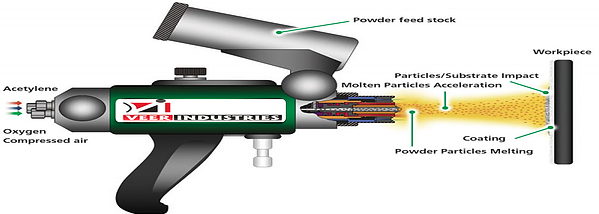

FLAM POWDER SPRAY COATING PROCESS

The Flame (or Combustion) Powder Spray process uses a similar technique as the Flame Wire Spray process, except that the wire feedstock is replaced with a powder. The main advantage of this process is that a much wider range of materials (such as nickel or cobalt based self fuxing alloys or ceramic materials) can be easily processed into powder form giving a larger choice of coatings. Many alloys are difficult or cannot be produced in a wire form and for this reason it was developed.

The process relies on the chemical reaction between oxygen and a fuel of combustion to produce a heat source. This heat source creates a gas stream with a temperature in excess of 3,000°C with correctly balanced conditions between oxygen and acetylene. The feed stock material to be sprayed is fed into the flame in the form of a powder to melt and the thermal expansion of the combustion is then used to atomize and accelerate the particles onto the substrate.

Typical coatings

- Self-fluxing alloys (fusing)

- Iron based alloys

- Nickel based alloys

- Ceramics & Cermets

- Abradables

Main applications

- Wear resistance

- Corrosion protection

- Chemical resistance

- Dimensional restoration