Project Description

WIRE ARC SPRAY COATING PROCESS

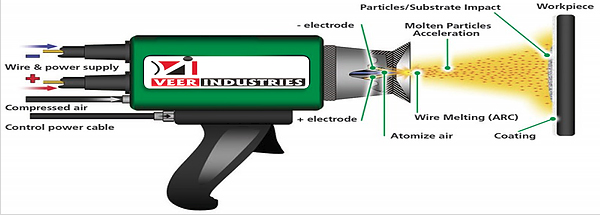

This form of thermal spraying uses wire material as a feed stock. An electric arc is used to provide the heat source by utilizing two current carrying wires. As the wires are fed towards each other the electric current short circuits between the wires creating a temperature of around 4,000°C. This temperature causes the tips of the wire to melt and once molten, compressed air or inert gas is used to atomize and accelerate the feed metal towards the substrate.

One of the advantages of this system is that two different wires can be used simultaneously to produce a pseudo alloy. Cored wires are also available producing coatings with unique properties.

The process is often used when applying to large areas such as corrosion resistance on large components or for the building up of worn components.

Typical coatings

- Iron based alloys

- Nickel based alloys

- Copper & Copper alloys

- Aluminium, Zinc, Al/Zn alloys

- Babbitt alloys

Main applications

- Wear resistance

- Corrosion protection

- Dimensional restoration

- Bond coat